From a safety standpoint, DemoFlex™ prevents Respirable Crystalline Silica Exposure during tile demo that causes harmful lung damage & diseases to workers and clients. Limit the amount of exposure that employers must contain after the fact instead; by using DemoFlex™ Tile Management Systems during tile installation. Silica is a microscopic component in most mortars, grouts and some tile; affecting the people working & living near its reach causing devastating harm to our bodies by attaching to our lungs while doing irreparable damage . OSHA has implemented new regulations to protect employees & even customers being exposed depending on the tasks being completed and length of exposure.

Silica Exposure Prevention

Among the other value that DemoFlex™ adds to the life of your floor, its feature of preventing respirable crystalline silica exposure, unique to DemoFlex™, will significantly improve your overall plan to regulate exposure that is mandated by OSHA’s new standards. Mitigating the dust after the fact is an option, but choosing to prevent it anywhere you can will make the entire workplace environment safer for workers & clients alike.

Depending on your given environments, workers may be required to wear both costly & efficiency robbing, custom fitted respiration devices (provided by the employer) while they work if their tasks and exposure rate is high enough…without DemoFlex™.

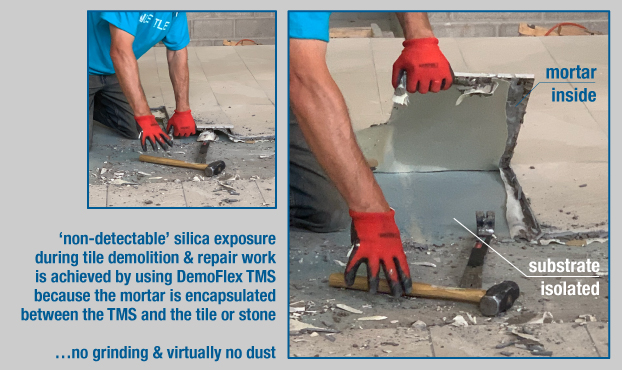

By encapsulating the mortar between the tile & membrane along with allowing the tiles to be removed in full pieces with no mortar left to grind, certified exposure testing completed utilizing DemoFlex reported that the exposure was so far below the Permissible Exposure Limit (PEL) 25 µg/m3 standard set by OSHA-1926.1153 that it was classified as “non-detectable” which is the lowest reportable level of exposure. This eliminates the need for extra engineering procedures accounting for tile demo using DemoFlex., reducing the need for regulated work-zones because exposure is so low and will not add to the OSHA PELs. The significantly faster tile demo process because of DemoFlex drastically reduces the potential risk of exposure as well.

Employers’ Potential Requirements:

⦁ Respirators (Assigned Protection Factors: 10-25)

⦁ Exposure Assessment

⦁ (Continued) Medical Surveillance of Employees

⦁ Familiarization & Training

⦁ Regulated Area Access Controls Blocking Clients & Other Employees

⦁ Written Exposure Control Plan

⦁ Engineering Controls (Task Dependent – see ‘table 1’)

Workers at increased risk of developing serious silica-related diseases, including:

⦁ Silicosis, an incurable lung disease that can lead to disability and death;

⦁ Lung cancer;

⦁ Chronic obstructive pulmonary disease (COPD); and

⦁ Kidney disease.

Major Types of Respirators Dependent on Tile Related Tasks Performed and Length of Work Shift Determine Which APF level is Required to be Provided by Employer.

See more from OSHA on the Silica: